Flexible transparent LED film is an innovative technology that allows for the integration of LED lighting into flexible, transparent surfaces. This technology can be used for various applications, including advertising displays, architectural lighting, and smart windows.

Components and Structure

Flexible Substrate:

The film is made from a flexible, transparent substrate, such as PET (polyethylene terephthalate) or other advanced polymer materials.

This substrate provides the base layer that supports the LED elements while allowing light to pass through.

LED Elements:

Tiny LED chips are embedded within the film. These LEDs can emit light in various colors, including RGB, to create dynamic and customizable displays.

The LEDs are arranged in a grid or matrix pattern, providing even light distribution.

Conductive Layers:

Transparent conductive layers, often made from materials like indium tin oxide (ITO) or silver nanowires, are applied to the substrate.

These layers allow electrical current to flow to the LED elements without obstructing visibility.

Encapsulation:

The entire assembly is encapsulated in a protective layer to shield the LEDs and conductive elements from environmental factors such as moisture and dust.

This encapsulation also contributes to the film’s flexibility and durability.

Working Mechanism

1.Electrical Power:

The LED film requires a power source to operate. This is typically provided through a low-voltage power supply, which is safe and efficient.

Power is supplied to the LED elements through the transparent conductive layers.

2.Light Emission:

When electrical current flows through the conductive layers, it powers the LED chips embedded within the film.

The LEDs emit light, which can be controlled in terms of brightness, color, and pattern.

3.Transparency Control:

The flexible transparent LED film is designed to maintain a high level of transparency when the LEDs are not illuminated.

The transparency is achieved by using small, evenly distributed LED elements and transparent conductive materials.

4.Flexibility:

The use of flexible substrates and encapsulation materials allows the film to bend and conform to various shapes and surfaces.

This flexibility makes it suitable for applications on curved surfaces, windows, and other non-flat installations.

Applications

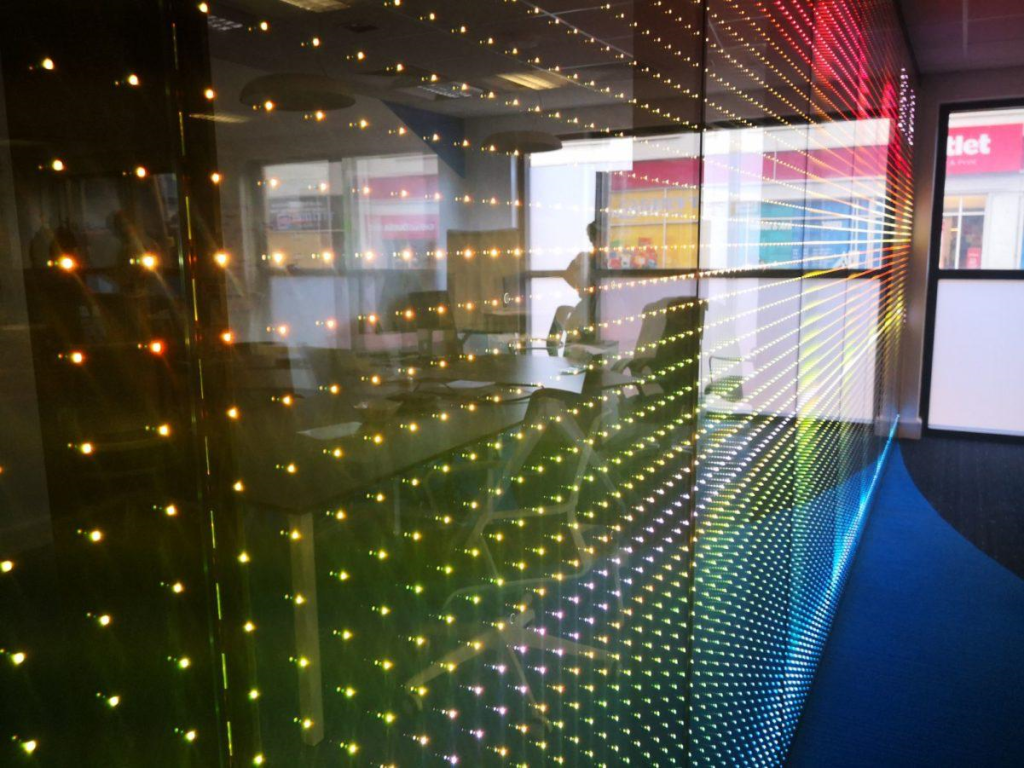

Advertising Displays:

Used in storefront windows and building facades to create eye-catching, dynamic advertisements.

Allows for the display of images, animations, and text without obstructing the view through the window.

Architectural Lighting:

Integrated into building surfaces to provide decorative lighting and dynamic visual effects.

Can be used in both interior and exterior applications, enhancing the aesthetic appeal of structures.

Smart Windows:

Applied to windows to create smart glass that can display information, advertisements, or decorative patterns.

Maintains transparency when not in use, allowing natural light to enter the space.

Retail and Exhibitions:

Enhances visual merchandising by adding dynamic lighting to product displays and exhibition booths.

Creates immersive and interactive experiences for customers and visitors.

Automotive:

Integrated into car windows and windshields for heads-up displays (HUDs) and interactive advertising.

Provides information and entertainment to passengers without obstructing visibility.

Wearable Technology:

Used in wearable devices and smart clothing to display information and dynamic patterns.

Combines flexibility and transparency with the functionality of LED lighting.